We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

tde

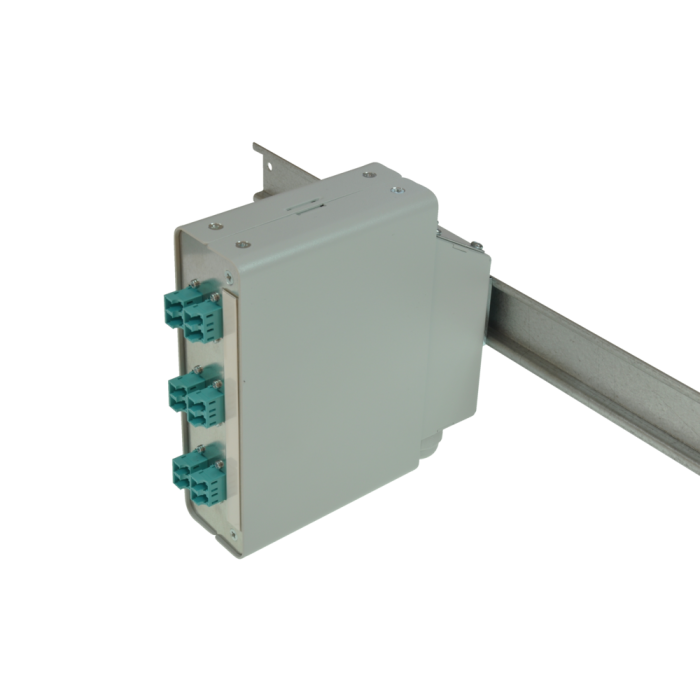

tBL® - DIN rail splice housing MM 3x LC Duplex OM4, splice ready prepared

Article ID

TBL-H06-03LCD50-4PS

tBL® - DIN rail splice housing MM 3x LC Duplex OM4, splice ready prepared

| Pre-mounted | 3 LC duplex adapters MM 6 LC Fiber pigtails 50/125µ OM4 2.0 meters tde attenuation class B, splice ready prepared 6 Crimp Splice protectors 1 Splice cassette 1 Splice holder 1 Cabel entry vertical 1 Mounting clip (for mounting on rail housing) 1 Gland M20 for cable entry |

| Alternative pre-mounted |

TBL-H06-xxLCD50-4Pyz (see below) |

| xx | (01 - 06) quantity of adapters |

| y | (S)plice ready prepared |

| z | With(O)ut Crimp Splice protectors |

tBL® - DIN rail splice housing, basic housing

| Housing | Alu-sheet, 1 mm |

| Dimensions | 141.4 x 141 x 42.8 mm |

| Colour | powdered in RAL 9005 (black) |

tBL® - FO Front panel 3U 8HP 6x SC Simplex for DIN rail splice housing

| Front panel | Alu-sheet |

| incl. labeling strip | |

| Configuration | Attachment up to 6x LC Duplex, 6x SC Simplex or 6x E2000 Simplex adapters |

LC Duplex Adapter Zirconia Straight Split with Flange, magenta

| Type | LC Duplex |

| Application | Multimode OM4 |

| Design | One-Piece with Flange |

| Connector style | SC Simplex |

| Color | Magenta |

| Material | Plastic |

| Sleeve | Zirkonia Staight Split |

| Shutter | - |

| Manufacturer | tde |

FO LC Simplex Connector tde class B for 50/125µ OM4 fiber

| Connector Type | LC Unibody Simplex |

| Housing | Plastic, Magenta |

| Ferrule | Zirkonia Staight Split, Spring-loaded Axially |

| Ferrule Hole | 126 µ |

| Mating Cycles | 1.000 |

| Operating Temperature | -40°C up to +75°C |

| Strain Relief to | 100 N |

| Manufacturer | tde |

| Fiber | Type | Wavelength | Insertion loss typ. | Insertion loss max. | Return loss min. |

|---|---|---|---|---|---|

| 50/125µ OM4 | LC | 850 / 1300 nm | ≤ 0.07 dB | 0.15 dB | 35 dB |

IL at 97% measured according to IEC 61300-3-4 under laboratory conditions.

FO Cables

| Tight Buffer | Low smoke (IEC 61034 and EN 50268) and free of halogens (LS0H) |

| Non corrosive after IEC 60754-2 and EN 50267 | |

| Flame resistent after IEC 60332-3C and EN 50266-2-4 | |

| Completly dry design | |

| Free from metal, no grounding problems and potential differences | |

| Tight Buffer for simple and direct connector mounting |

| Fiber Count | 1 (Tight Buffer) |

| Core-Ø | 0.9 mm |

| Coreweight | 1 kg/km |

| Min. Bending radius - Installation | 30 mm |

| Min. Bending radius - Operation | 30 mm |

| Removal | 1500 mm |

|

Fire load |

0.15 MJ/m |

|

Temperature range - Installation |

-5 to +50°C |

|

Temperature range - Operation |

-20 to +60°C |

|

Temperature range - Transport / Lagerung |

-25 to +70°C |

Corning FO ClearCurve® 50/125µ OM4 multimode fiber

| Type | Corning ClearCurve® 50/125µ OM4 multimode fiber |

| Optimized Data Rate over Distance | 40/100 Gb over 170 m* 10 Gb/s over 550 m 1 Gb/s over 1100 m |

| Standard Compliance | ISO/IEC 11801: type OM4 fiber** IEC 60793-2-10: type A1a.3 fiber** TIA/EIA: 492AAAD ITU: ITU G651.1 |

| * | Distances specified in the 40G/100G per IEEE 802.3ba standard are 150m on OM4 and 100m on OM3; Corning fibers are manufactured to tighter dispersion specifications and thereby support the extended distances shown in the table (assuming cable attenuation ≤3.0 dB/km and same 1.0 dB of connector loss for OM3 that the standard requires for OM4) |

| ** | Assumes IEC draft standard is harmonized with 492AAAD which was approved by TIA |

| Bandwidth | High Performance EMB* (MHz.km): 4700 at 850 nm only Legacy Performance EMB** (MHz.km): 3500 at 850 nm / 500 at 1300 nm |

| Attenuation | At 850 nm max. ≤ 2.3 dB/km At 1300 nm max. ≤ 0.6 dB/km |

| Macrobend Loss | Mandrel Radius (mm): 37.2 / 15 / 7.5 Number of Turns: 100 / 2 / 2 Induced Attenuation (dB) at 850 nm: ≤ 0.05 / ≤ 0.1 / 0.2 Induced Attenuation (dB) at 1300 nm: ≤ 0.15 / ≤ 0.3 / ≤ 0.5 |

| Numerical Aperture | 0.200 ± 0.015 |

| * | Ensured via miniEMBc, per TIA/EIA 455-220A and IEC 60793-1-49, for high performance laser-based systems (up to 10Gb/s) |

| ** | OFL BW, per TIA/EIA 455-204 and IEC 60793-1-41, for legacy and LED-based systems (typically up to 100 Mb/s) |

| Core Diameter | 50.0 ± 2.5 µm |

| Cladding Diameter | 125.0 ± 1.0 µm |

| Core-Clad Concentricity | ≤ 1.5 µm |

| Cladding Non-Circularity | ≤ 1.0% |

| Core Non-Circularity | ≤ 5.0% |

| Coating Diameter | 242 ± 5 µm |

| Coating-Cladding Concentricity | < 12 µm |

| Enviromental Test | Test Condition | Induced Attenuation 850 nm & 1300 nm (dB/km) |

|---|---|---|

| Temperature Dependence | -60°C to +85°C | ≤ 0.10 |

| Temperature Humidity Cycling | -10°C to +85°C and 4% to 98% RH | ≤ 0.10 |

| Water Immersion | 23°C ± 2°C | ≤ 0.20 |

| Heat Aging | 85°C ± 2°C | ≤ 0.20 |

| Damp Heat | 85°C at 85% RH | ≤ 0.20 |

| Operating Temperature Range | -60°C to +85°C |

| Proof Test | The entire fiber length is subjected to a tensile stress ≥ 100 kpsi (0.7 GN/m²). |

| Length | Fiber lengths available up to 17.6 km/spool. |

| Refractive Index Difference | 1% |

| Effective Group Index of Refraction | 850 nm: 1.480 1300 nm: 1.479 |

| Fatigue Resistance Parameter (nd) | 20 |

| Coating Strip Force | Dry: 0.6 lbs (2.7N) Wet: 14 days in 23°C water soak: 0.6 lbs (2.7N) |

| Cromatic Dispersion | Zero Dispersion Wavelength (λ0): 1295 nm ≤ λ0 ≤ 1315 nm Zero Dispersion Slope (S0): ≤ 0.101 ps/(nm²*km) |

tBL® - splice cassette for DIN rail splice housing

| Type | splice cassette for DIN rail splice housing |

| Material | sheet steel |

| Colour | powdered in RAL 9005 (black) |

| Configuration | uo to 2x 12 splices |

FO Splice holder for 12x crimp splice protectors

| Type | FO Splice holder for 12 x Crimp splice protectors |

| Dimensions | 40 x 26 x 6 mm |

| Material | Bright ABS, similar RAL 1013 |

FO crimp splice protector

| Type | Crimp splice protector |

| Dimensions | 31 x 3 x 1 mm |

| Delivery time | 5-10 working days |

|---|---|

| Manufacturer | tde |

| Systems | tBL® - tde Basic Link (FO Enclosures) |

| Category | FO DIN rail splice module Premium |

| Mediaobjects | |

| Connector type (side 1) | LC Duplex, LC Simplex |

| Fiber type | 50/125 µm OM4 |

| Type | LC |

| Adapter color | Magenta |

| Material | Stahlblech |

| Patch panel type | tBL® - FO DIN Rail Module |

We found other products you might like!