We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Search results for: 'value chain'

- Did you mean

- value coin

- value chip

- Related search terms

- value based care

- Value of cos 2x

- value 1960 5 francs

- value 1000 5 frnc

- value 1260 5 frnc

-

tde FO indoor and outdoor cable 4E9/125µ OS2 Corning Ultra Fiber, PUR, black L-A-V(ZN)11Y04E09XExcl. 19% VAT

tde FO indoor and outdoor cable 4E9/125µ OS2 Corning Ultra Fiber, PUR, black L-A-V(ZN)11Y04E09XExcl. 19% VAT -

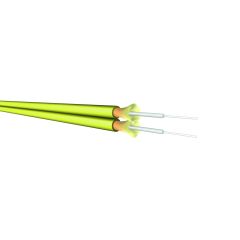

tde FO Duplex cord 50/125µ OM5 LSOH 2,0mm L-IVH02G50-2,0-OM5LGExcl. 19% VAT

tde FO Duplex cord 50/125µ OM5 LSOH 2,0mm L-IVH02G50-2,0-OM5LGExcl. 19% VAT -

tde tML® Xtended - FO Dark Fiber Module 4x MPO/MTP® w/o Pins/6x MPO/MTP® w. Pins 50/125µ OM3, SR4 TML-M06MPP/04MP50G3XExcl. 19% VAT

tde tML® Xtended - FO Dark Fiber Module 4x MPO/MTP® w/o Pins/6x MPO/MTP® w. Pins 50/125µ OM3, SR4 TML-M06MPP/04MP50G3XExcl. 19% VAT -

tde FO Patch cord LC/LC tde 50/125µ OM5 Duplex MiniZip LSOH Length: xxxxx L-LC/LC50D5MxxxxxExcl. 19% VAT

tde FO Patch cord LC/LC tde 50/125µ OM5 Duplex MiniZip LSOH Length: xxxxx L-LC/LC50D5MxxxxxExcl. 19% VAT -

tde FO Patch cord LC/LC tde 50/125µ OM5 Duplex MiniZip LSOH Length: xxxxx P-LC/LC50D5MxxxxxExcl. 19% VAT

tde FO Patch cord LC/LC tde 50/125µ OM5 Duplex MiniZip LSOH Length: xxxxx P-LC/LC50D5MxxxxxExcl. 19% VAT -

tde tML® 24+ - FO Dark Fiber Module 4x 24F MMC without Pins/12x 12F MPO/MTP® with Pins 50/125µ OM5, SR4 TML-M12MPP/04MM2-50G5Excl. 19% VAT

tde tML® 24+ - FO Dark Fiber Module 4x 24F MMC without Pins/12x 12F MPO/MTP® with Pins 50/125µ OM5, SR4 TML-M12MPP/04MM2-50G5Excl. 19% VAT -

tde tML® 24+ - FO Dark Fiber Module 2x 24F MMC without Pins/6x 12F MPO with Pins 50/125µ OM5, SR4 TML-M06MPP/02MM2-50G5Excl. 19% VAT

tde tML® 24+ - FO Dark Fiber Module 2x 24F MMC without Pins/6x 12F MPO with Pins 50/125µ OM5, SR4 TML-M06MPP/02MM2-50G5Excl. 19% VAT